Michelle Bryson is the Global Sustainable Packaging Leader for BW packaging Systems. The following content contains excerpts from her interview with Packaging Europe, on Synerlink's Snapcut technology for thermoforming filling machines, which originally appeared on packagingeurope.com on September 13, 2022.

I had been working as the Global Sustainable Packaging Leader at BW packaging systems only a few months when I submitted the application for Synerlink’s Snapcut innovation. When I received the news that Synerlink

was shortlisted among the finalist's roster for Packaging Europe’s Sustainability Awards, I was thrilled for the team! Synerlink’s

R&D team undertook an impressive, proactive approach to solving our customers' challenges with running sustainable materials on their FFS equipment. This work spanned 2 years. They leveraged their deep packaging material knowledge, studied

a vast array of different cutting tool materials, and conducted multiple bench-top to scale up tooling designs to

provide the desired levels of performance, backing them with a lifetime of

customer support.. So, I was more than happy to answer Packaging Europe’s questions

regarding this innovation.

What is Snapcut?

First thing’s first, what is Snapcut?

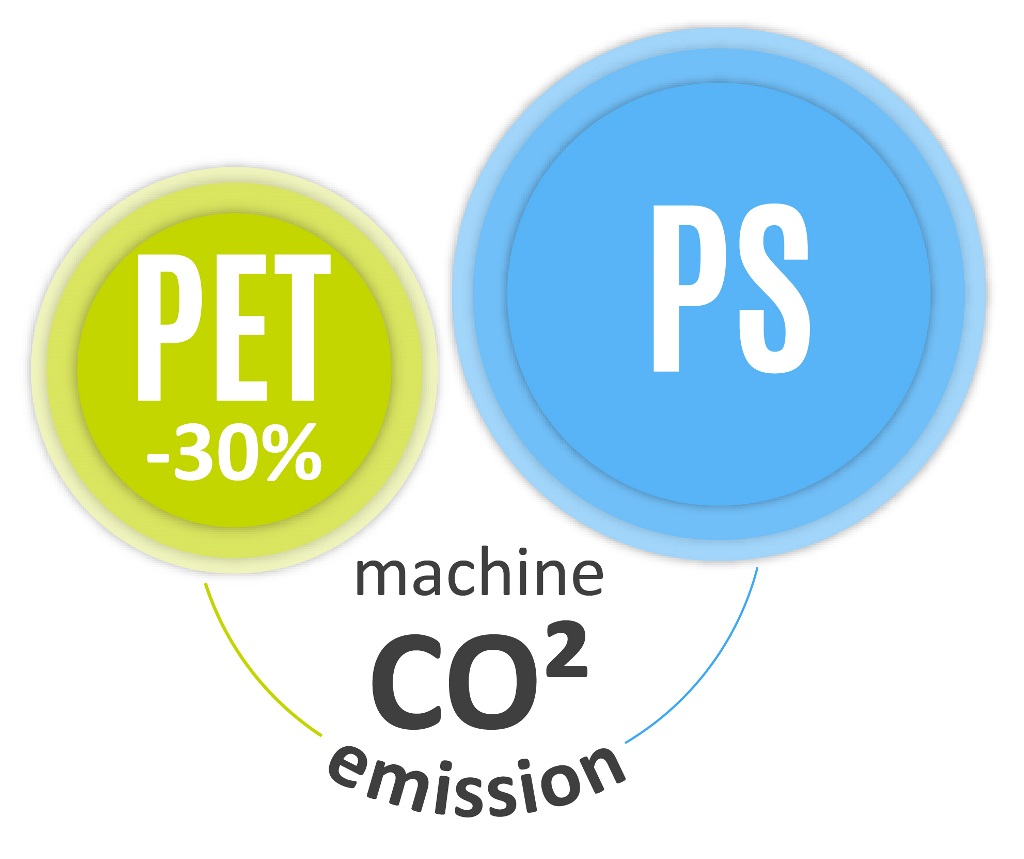

This cutting-edge cutting technology (pun intended) is a tool that allows for the pre-cutting and cutting of recyclable and recycled materials like PET, rPET,PLA, PS, rPS and PP/EVOH/PP. The Snapcut tool was conceived for Form Fill Seal (FFS) applications

to assure the quality and safety of cutting and packaging without hindering the production rate.

The Snapcut tool was developed to respond to our clients' needs to run recycle-friendly materials to reach their internal sustainability goals and to propose environmental-friendly solutions to the market on thermoforming machines. This solution was also designed with governmental actions against single-use plastic and efforts toward a circular economy in mind.

View a video of Snapcut here:

What are the results of this technology?

Our engineers have worked hard for 2 years to develop Snapcut, a technology capable of cutting plastic of 0.6mm thickness that would assure quality and safety. It was of utmost importance for Synerlink that this technology would not only be optimized

for new machines but that it could also be installed on existing thermoforming machines to allow our client base to benefit from this tool without investing in new machinery.

After 2 intense years of R&D, our engineers have been able to create a tool that allows pre-cutting and cutting of multipacks. The process involved various lab equipment, developing testing protocols and collection of data. Although, the factor that

really made this development possible was the internal know-how of Synerlink’s team of specialists, who have expertise in resin characteristics, performance and restrictions of the various materials. Nowadays, Synerlink can count on a dedicated

materials laboratory to study future applications of its cutting technologies.

How has your innovation/initiative been received?

This technology has proven successful in the food processor market with thermoforming filling solutions. We were able to design and build new machines processing Polypropylene (PP) and Polyethylene terephthalate (PET) for players wanting to expand their

production to provide recyclable or recycled packaging. Although, the most important success for Synerlink was upgrading many different machines that were already in the market, effectively skipping all the waste creation and material consumption

needed to discard an old machine and build a new one to run these plastics.